Close The Door on Inefficiency

Executive Summary

This case study explores how WAVE supported ALDI, a leading food retailer to tackle inefficiency in refrigeration and reduce their carbon footprint. This was achieved through the implementation of doors on all chilled display cases in their stores. ALDI achieved significant energy savings, cost reductions, and environmental benefits by completing this project.

The implementation process involved WAVE experts working closely with ALDI to analyse the existing refrigeration systems, evaluate potential solutions, and assist ALDI with an international tender to source the optimal doored refrigerated display cases. The project was managed by WAVE and prioritised efficiency improvements whole managing the impact on capital costs or maintenance.

The collaboration between ALDI and WAVE resulted in substantial positive outcomes. By utilizing doors on the refrigerated display cases, ALDI was able to reduce refrigeration duties and increase evaporation temperatures, leading to lower energy consumption and improved store temperatures. The implementation process, results obtained, and overall success of ALDI’s initiative are presented in this case study.

Figure 1: Doored Refrigerated Display Cases in Aldi Store

Introduction

WAVE’s support encompasses a range of services from Refrigeration, HVAC, Design, Project management and technical evaluation services. Our analysis goes beyond simple cost comparisons, incorporating factors such as emissions, energy expenditure, and operational impact.

ALDI Süd is a global retailer known for providing high-quality products at affordable prices. With a strong emphasis on efficiency and customer satisfaction, ALDI Süd has carved out a prominent position in the retail industry. Currently Operating in 11 different countries, ALDI Süd offers a diverse range of goods, including groceries, household essentials, and specialty items. Sustainability is a core value for ALDI Süd. The company strives to minimize its environmental impact by implementing eco-friendly practices throughout its operations, including efficient energy usage, waste reduction, and responsible sourcing. ALDI Süd actively supports initiatives that promote sustainability and social responsibility.

As sustainability becomes increasingly important in the retail industry, ALDI embarked on a mission to enhance efficiency and reduce their environmental impact. One key aspect of their strategy was to introduce doors on chilled display cases across their entire store estate. This case study examines how ALDI partnered with WAVE to achieve their sustainability goals, offering insights into the challenges faced, the implementation process, and the positive outcomes obtained.

The Challenge

ALDI aimed to cut indirect CO2 emissions by improving energy usage in their stores. They had already surpassed their target sustainability target to have 25% of their estate operating on CO2 by the end of 2020. The next step was to cut indirect CO2 emissions through a reduction in energy consumption. WAVE identified fitting refrigerated display cases with doors would offer significant energy savings. ALDI commit to utilizing doors on all new and refurbished stores from the beginning of 2021. The challenge was to find a solution that would be to evaluate and select the optimal solution to maximise energy reduction, while also considering capital costs and total cost of ownership.

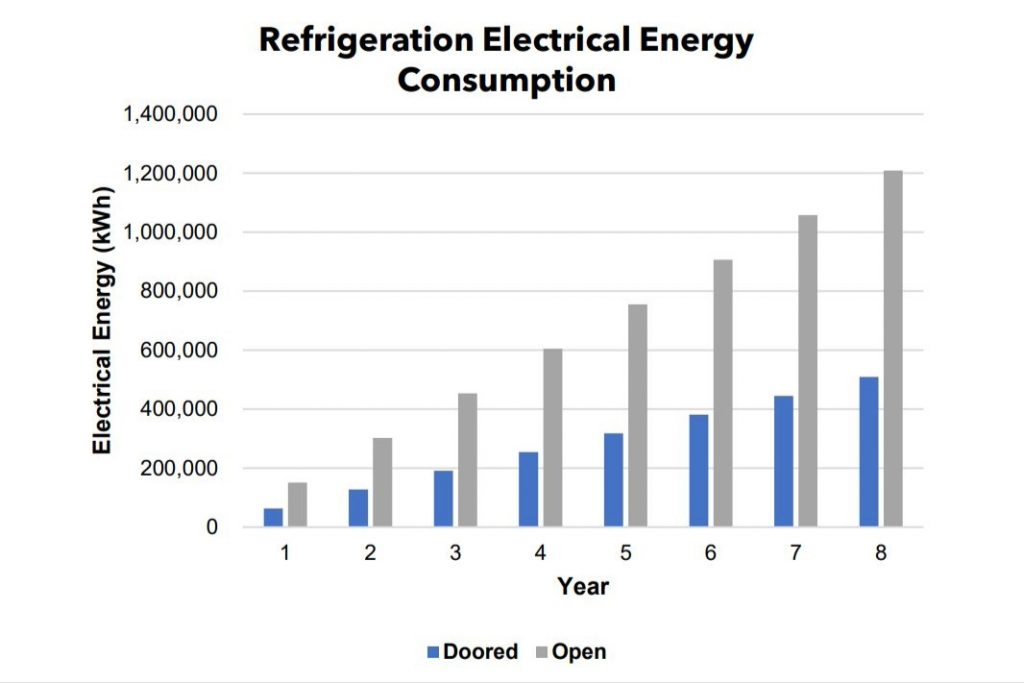

Figure 2: Overview of heat transfer of open and doored cases

Implementation

To address the challenge of reduction of energy consumption, the concept was simple. By fitting doors this would reduce energy consumption through reduced refrigeration duties and increased evaporator temperatures. WAVE supported Aldi and a series of store trials aimed at retrofitting open chilled display cases with light acrylic doors took place. While this initial approach showed some promise, it became apparent that it did not provide the desired energy savings.

Recognizing the need for a more effective solution, WAVE carried out a detailed analysis showing the reduction in cold air spillage form retrofitted doors and “True-Doored” cases. The results of this study clearly showed that open display cases with doors retrofitted although the evaporating temperature can be increased, and duty will reduce but savings will not be optimal. However, ‘True-Doored’ cases – designed to operate with doors and have much improved airflow for use with doors. In addition, the study quantified the effect of doors in reducing the heat requirement for the store as they prevented cold air from escaping and warm air from entering.

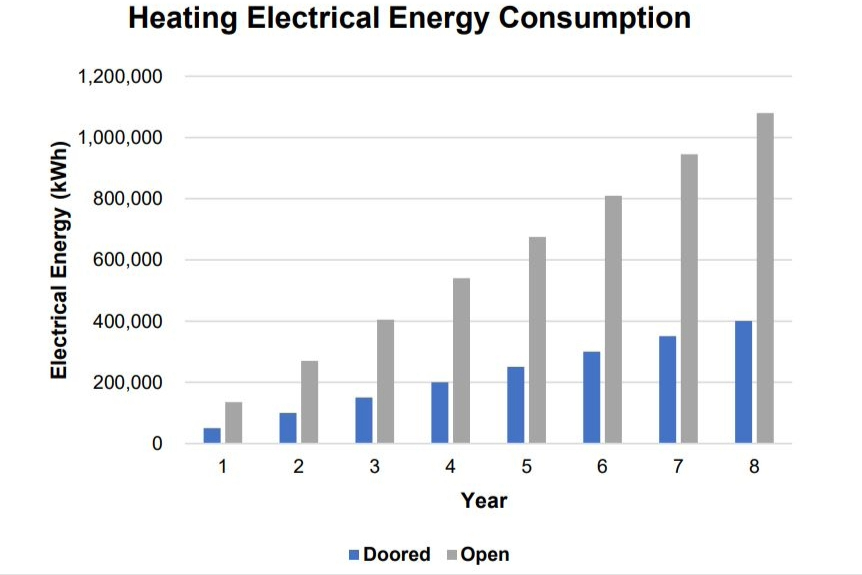

The next stage in the project involved WAVE measuring the impact that chilled doors have on the refrigeration plant. This involved assessing the energy consumption modelling for different display case options – Open display cases and Doored display cases. The positive impact on heating load was quantified by determining the cooling effect of various display case options and apportioning this load to be offset by an air source heat pump. The resulting difference in refrigeration and heating energy consumption associated with the display cases used has a profound effect on the total energy consumption.

With the impact on the store modelled the next step was to evaluate the impact on capital cost and return on investment. After a detailed assessment WAVE found that on average cabinet costs in a store with doored cabinets cost 52% more than ones with open fronted cases. However, to offset this the reduction in overall refrigeration capacity for the store reduced from 67%. This had the effect of reducing the overall cost of refrigeration plant on average by 27%. So overall the combined impact on CAPEX (Capital expenditure) was on average a 5% increase.

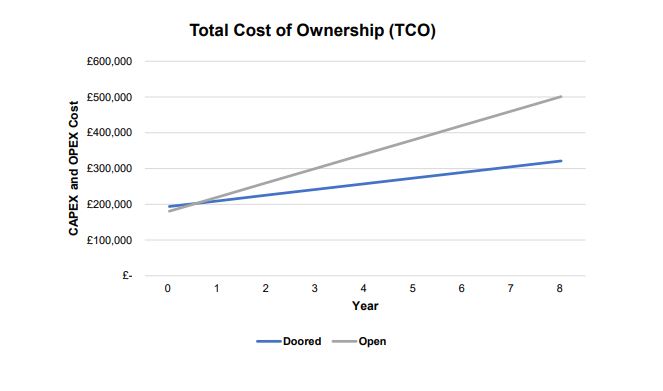

Finally, the last step was to review the total cost of ownership and life cycle costs to demonstrate the return on investment for the doored cabinets.

Figure 3: Graphs outlining differences in energy consumption for open and doored cases

Results and Benefits

Financially, although doored cases were more expensive upfront, the plant redesign and reduced refrigeration capacity helped to offset some of the CAPEX increase. The substantial energy savings offered by reduction in refrigeration duty and increase in evaporation temperature easily offset the increased capital cost. This resulted in a return on investment of less than 12 months. The Total Cost of Ownership (TCO) savings over an 8-year period amounted to £183,000 per store. If this was extrapolated across the planned new stores and refits over the next 3 years Energy savings would total £41 million, accompanied by TCO savings of £39 million. Moreover, the adoption of doored display cases allowed ALDI to make substantial environmental contributions. Each store using these cases saved 322 tonnes of CO2 emissions over an 8-year period, equivalent to planting nearly 2,000 trees. With plans to complete over 200 installations in the next 3 years, it was projected these would save 66,666 tonnes of CO2, equivalent to planting over 400,000 trees.

In addition, there was a few additional benefits established by using doored cabinets. Firstly, as the evaporators are moved to the base of the cabinets this creates a narrower footprint case and allows for wider aisles in the store. Secondly the reduction in old air spillage from the cases led to a significant improvement of store temperatures.

Figure 4: Graph showing return on investment for doored cases

Conclusion

By implementing doors on chilled display cases with the assistance of WAVE, ALDI successfully closed the door on inefficiency and achieved remarkable sustainability benefits. The reduction in energy consumption, plant redesign, and environmental improvements demonstrated ALDI’s commitment to innovation and aligning with their ESG goals.

Key takeaways from project are:-

- Fitting doors on your refrigerated display cases can reduce your refrigeration load by up to 2/3rds.

- Although the capital costs are higher for doored cases some of the expenditure is offset by reduction in refrigeration plant size.

- Energy savings are substantial, and the payback is less than 12 months.

- Rolled out across a retail estate offers enormous cost, energy and environment benefits to the retailer.